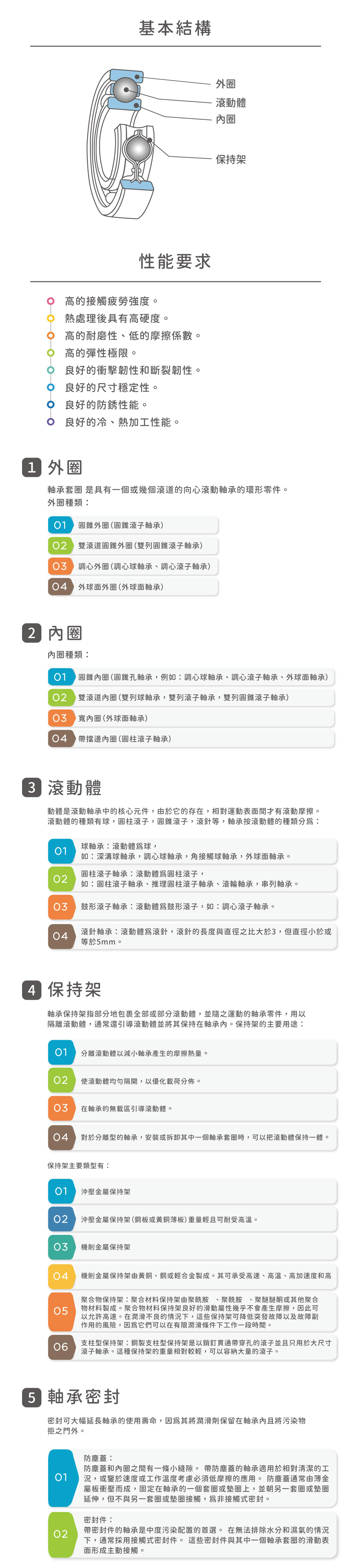

軸承鋼 (SUJ)

軸承鋼主要用於製造滾動軸承的滾動元件和軸承環,有時也用來製造工具,如沖模、量具等,軸環採用熱鍛直棒、磨光棒,鋼珠用保安級軸承鋼線。軸承鋼應具有高的硬度、耐磨性、韌性、高彈性限和疲勞強度。 標準的化學成分為0.9~1.2%碳、0.2~0.6%矽、0.5%以下或0.9~1.2%錳、1.0~1.5%鉻及少量的磷與硫(0.03%)等。 雖然軸承鋼的成分與合金工具鋼相近,但因其純度、煉鋼法、高溫加工與熱處理等皆需特別處理。

製造滾珠軸承、滾子軸承、滾針軸承等固定機件的材料。需具有精度高、硬度高、耐磨耗、韌性大、高疲勞限度等特性,其合金元素有碳、鉻、錳、鉬、矽及少量的硫、磷。

軸承鋼一般分為五類:

2.jpg)