高速工具鋼 (SKH)

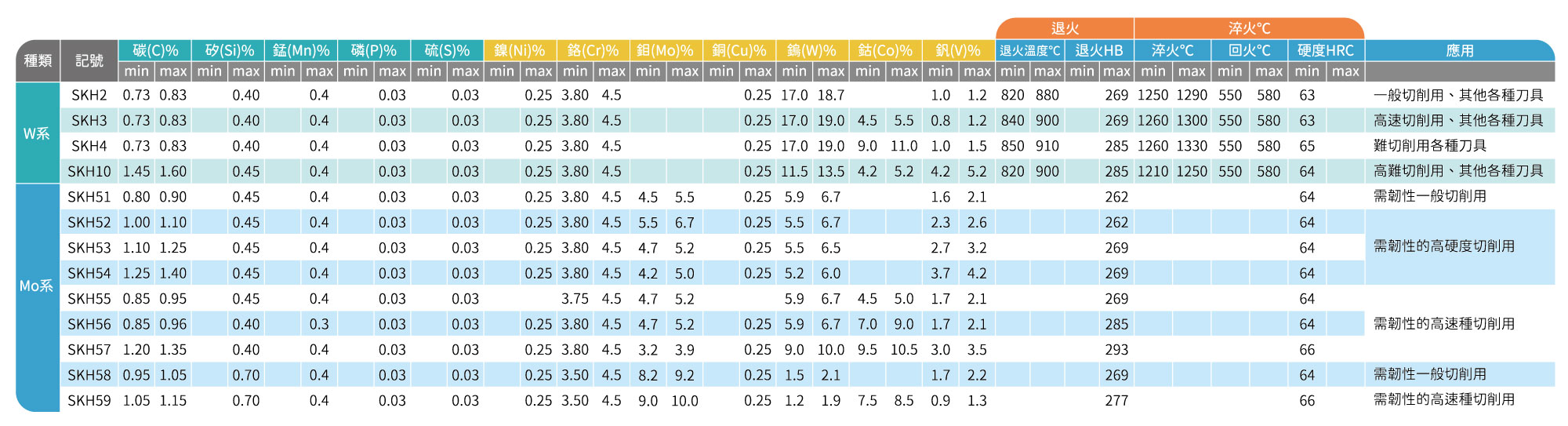

高速鋼主要用於製造高效率的切削刀具。在高速切削時其刀具刃口因摩擦而產生高熱(約 600℃),仍然不致使鋼發生退火軟化,高速工具鋼主要用於製造高效率的切削刀具, 具備熱硬性、耐磨性、高強度且保持其硬度及切削能力稱為高速鋼。因在高溫不但不易軟化反而增加硬度,此稱為紅熱硬性或二次硬化。 高速鋼的種類繁多,可分為鎢系、鉬系、鎢鉬系、釩高速鋼、鈷高速鋼五大類;按性能可分低合金高速鋼、普通高速鋼、高性能高速鋼。 W鎢系高速鋼 : 鎢系高速鋼因鎢之含量高達12w.t.%,具有高強度、硬度及耐磨耗性,以JIS SKH2 ~ 10為代表。 Mo鉬系高速鋼 : 鉬系高速鋼韌性最高,具有適當之耐熱及耐磨耗性,以JIS SKH51 ~ 59為代表。