Product Applications

AISI 4140

AISI 4140 It has very high strength, wear resistance, impact

MOREAISI 4140

AISI 4140 It has very high strength, wear resistance, impact resistance, toughness and torsional strength.

AISI 4140 alloy steel is similar to AISI 4130, but has a slightly higher carbon content, which results in better strength and heat handling properties, but also has poorer welding properties compared to AISI 4130 because of the slightly higher carbon content.

The machinability of AISI 4140 alloy steel is better in the annealed condition.

However, since AISI 4140 alloy is harder than ordinary carbon steels, it requires more pressure to form.

Typical uses are thin-walled pressure vessels, forged gears and shafts (motor shafts, pump shafts, hydraulic shafts, etc.), spindles (lathe spindles, milling spindles, etc.), shaft rings, clamps, high-strength bolts, valve caps, screws, nuts, worm gears, clevises, torsion bars, and various carburized parts.

AISI 4140 alloy steel is used in the U.S. for ASP throwing rods.

Translated with www.DeepL.com/Translator (free version)

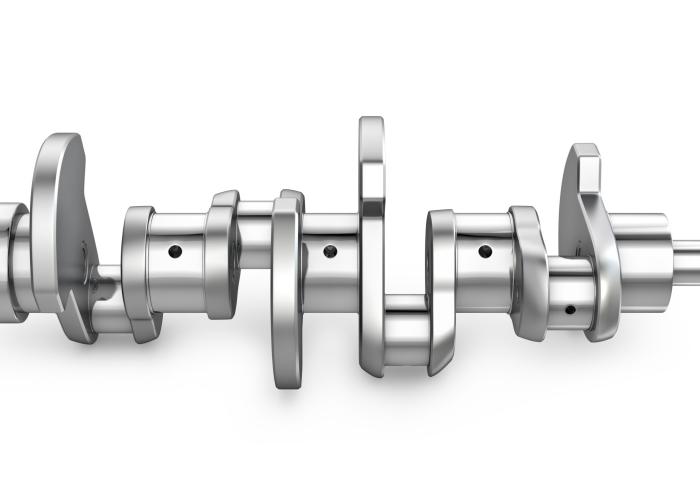

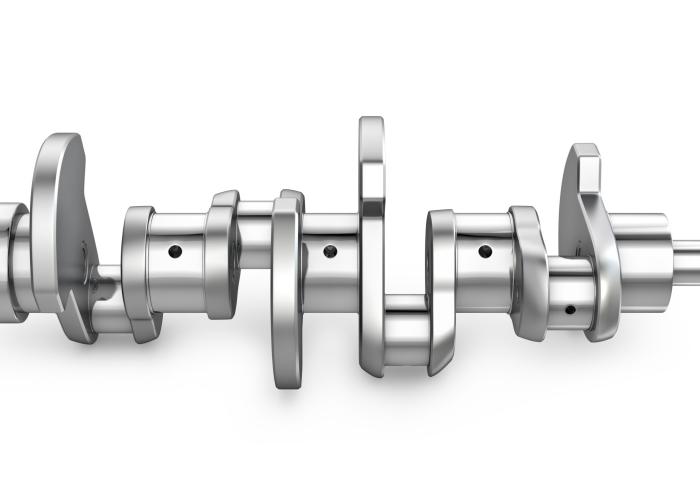

AISI 4340

AISI 4340 steel (UNS G43400) is an ultra-high strength mediu

MOREAISI 4340

AISI 4340 steel (UNS G43400) is an ultra-high strength medium carbon low alloy steel, which combines deep hardenability, high ductility, toughness and strength, and has high fatigue resistance and creep resistance.

It is not particularly affected by tempering and embrittlement, and exhibits good strength retention at high temperatures and is not easily softened. In thin sections, this steel is air-hardened. In practice, it is usually oil quenched.

SAE AISI 4340 steel is usually used in places where severe conditions exist and heavy parts requiring high strength, and can be widely used as billet, bar, bar, forging, sheet, pipe and welding wire.

AISI 4340 steel can also be produced as light plates and castings. Typical applications include bolts, screws and other fasteners.

Gears, pinions, shafts and similar mechanical components; crankshafts and piston rods of engines; and landing gear and other key structural components of aircraft.