Corrosion-Resisting Stainless Steel (SUS)

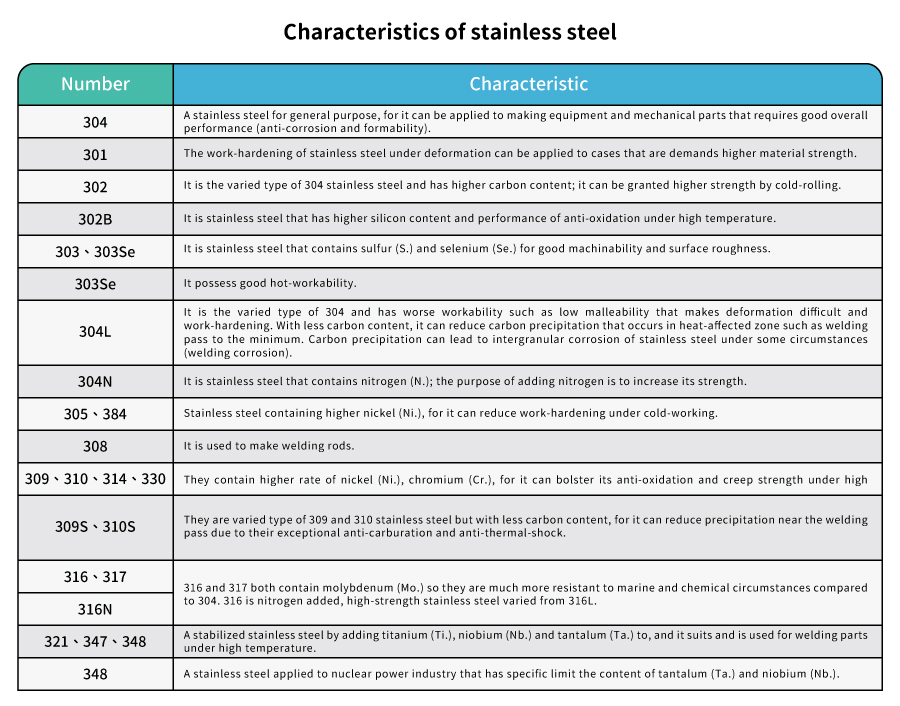

Corrosion-resistant stainless steel is a high-performance alloy known for its excellent resistance to corrosion, oxidation, and mechanical stress. It performs reliably in harsh environments involving acids, alkalis, and salts without rusting. Chromium (Cr) is the key alloying element, often combined with nickel (Ni), molybdenum (Mo), or manganese (Mn) to further enhance performance. Based on microstructure and composition, stainless steels are classified into austenitic, ferritic, martensitic, duplex, and precipitation hardening types. These steels are widely used in medical devices, food processing, chemical equipment, construction, and marine applications.