Free Cutting Steel (SUM, SCM)

Free-cutting steel is carbon steel with a small amount of sulfur, lead, manganese, and other elements added to improve cutting performance, making it easier to process.

It adds alloy elements to the steel such as:

Lead (Pb), Sulfur (S), Phosphorus (P), among which sulfur (S) is the most commonly used. It forms MnS in the steel, which makes the chips turn into thin or short discontinuous chips during cutting. These elements also have a lubricating effect, enhancing the cutting process and improving the surface finish of the processed area.

Adding 0.1~0.3% lead to carbon steel or alloy steel can further improve the machinability of the steel, as lead does not dissolve in iron in any state but is uniformly distributed in the steel in the form of monomer particles. During cutting, lead acts as a solid lubricant, making the chips easy to break without affecting the mechanical properties of the steel.

Generally, based on the added elements, free-cutting steel can be divided into two types:

(1) Sulfur-based free-cutting steel (2) Lead-based free-cutting steel.

Both are not suitable for forging, cold work forming, and welding, etc.

Free-Cutting Steel

n Added Elements

Usually high sulfur (S) or lead (Pb) elements are added.

n Classification of Free-Cutting Steel

(1) Sulfur-Based Free-Cutting Steel

1. Added Elements: Sulfur (S)

2. Features: (1) Good cutting performance (2) Suitable for mass production (3) High-speed cutting

(2) Lead-Based Free-Cutting Steel

1. Added Elements: Lead (Pb), Sulfur (S)

2. Features: (1) Excellent cutting performance (2) Good surface finish

n Surface Finish

The surface finish after processing is high, suitable for producing parts that require high surface quality.

n Application Range

Widely used in automatic lathes, CNC machine tools, and other high-efficiency production equipment,

mainly used for manufacturing various screws, bolts, rivets, and other automated machinery parts.

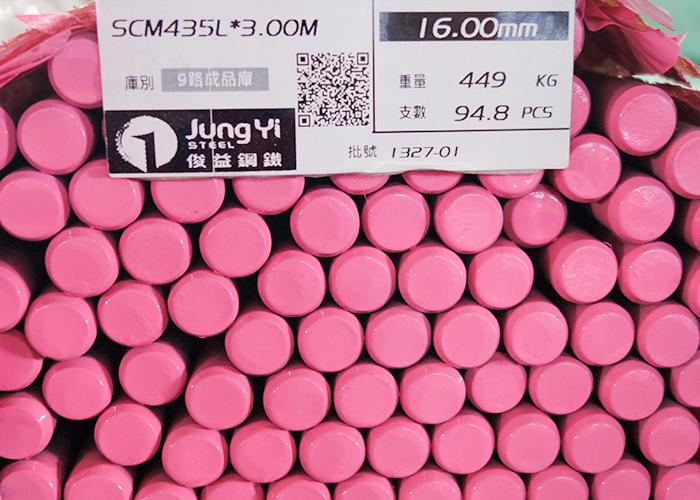

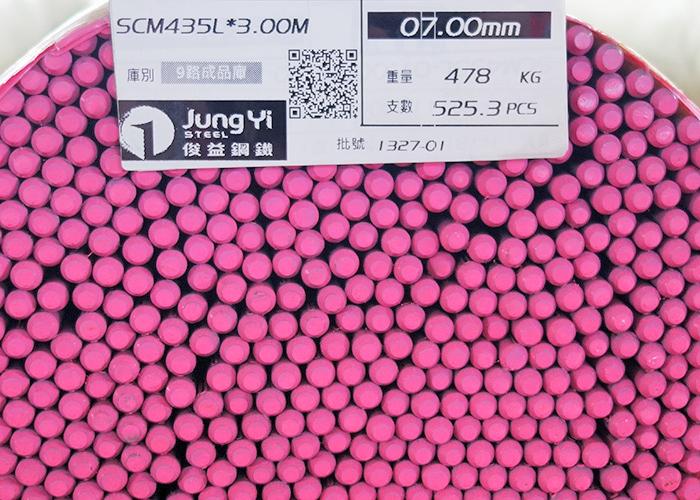

Free-Cutting Alloy Steel

n Characteristics

Alloy elements such as molybdenum (Mo), nickel (Ni), chromium (Cr) are added to the base steel,

these elements improve the mechanical properties and corrosion resistance of the material.

Sulfur, lead, and other elements are also added to maintain good cutting performance.

n Machining Performance

Free-cutting alloy steel also contains elements like sulfur and lead, maintaining good cutting performance,

while possessing excellent mechanical properties and wear resistance.

n Strength and Hardness

Compared to ordinary free-cutting steel, free-cutting alloy steel has higher strength and hardness,

suitable for manufacturing high-load, wear-resistant parts.

n Application Range

Widely used in manufacturing parts requiring high strength and high wear resistance, such as automobile parts, aerospace components, and high-performance machinery equipment.

n Machining Advantages

1. Efficiency Improvement:

Free-cutting steel and free-cutting alloy steel can significantly shorten machining time, improve production efficiency, and are suitable for mass and automated production.

2. Cost Reduction:

Excellent cutting performance reduces tool wear, lowering tool replacement frequency and processing costs.

3. Quality Assurance:

High surface finish and precision improve product quality, reducing the need for subsequent processing and finishing.