Structural Steel with Specified Hardenability Bands

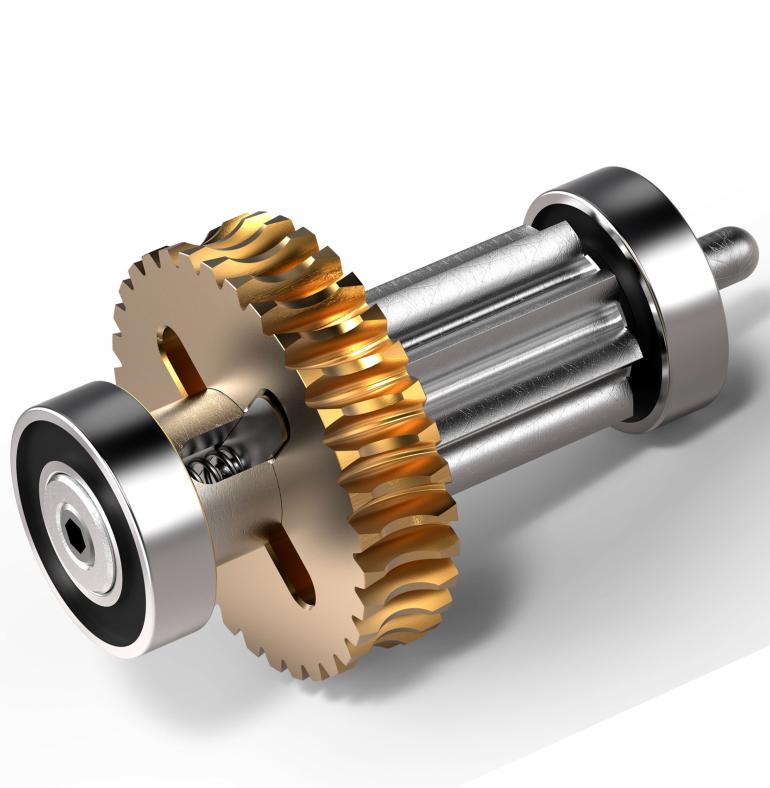

H steel is guaranteed heat-treated steel, where hardness distribution is controlled within the "H" shaped tempering curve after quenching and tempering, providing strong toughness. Its structure is ideal, with a hard outer shell and a tough core, offering wear resistance and fatigue strength while maintaining internal impact toughness. These properties are achieved through carburizing, quenching, and tempering, making H steel suitable for high-load parts such as gears, bearings, and drive shafts, commonly used in automotive and heavy machinery industries.

Hardenability

Hardenability refers to the ability of steel to be hardened through a quenching process, which is also known as "quenchability."

Hardenability indicates the depth to which steel can be hardened under a given quenching condition.

It is important to note that the degree of hardenability does not determine the maximum hardness that can be achieved, but rather how deep the steel can be hardened during quenching.

The so-called "H" steel refers to guaranteed heat-treated steel, where the hardness distribution after heat treatment is assured to remain within the upper and lower limits of the "H" shaped tempering curve.

This type of steel is characterized by high toughness.

Mass Effect

Mass effect refers to the variation in quenching results depending on the size of the treated component.

There is a reciprocal relationship between mass effect and hardenability: a large mass effect is often due to poor hardenability;

conversely, steel with good hardenability has a smaller mass effect and can achieve deeper hardening during quenching.

1. Influence of Cooling Medium

The cooling medium used during quenching significantly impacts the hardening depth. Common cooling media include:

Gas Quenching: Uses nitrogen or helium as a cooling medium, with a slower cooling rate. It is suitable for steels with good hardenability and reduces the risk of quenching distortion.

Polymer Quenching Solutions: These cool at a rate between water and oil quenching, allowing for precise control of the cooling speed, ideal for applications requiring accurate cooling rates.

Salt Bath Quenching: Provides uniform and rapid cooling, suitable for large components, reducing internal residual stresses and cracking risks.

2. Hardenability Curve (Jominy End-Quench Test)

The Jominy End-Quench Test is a standard test to assess steel's hardenability.

By measuring hardness at different positions along a steel bar, it is possible to understand the hardening effect at different cooling rates.

Testing Procedure: One end of a standard steel bar is cooled, and hardness is measured at various points to plot the hardenability curve.

Curve Interpretation: A flatter curve indicates better hardenability; a steeper drop signifies poorer hardenability.

Applications: It helps select the right steel for thick sections or parts requiring a specific hardening depth.

3. Influence of Alloying Elements on Hardenability

The type and content of alloying elements directly affect the steel's hardenability:

Carbon (C): Increases hardness but has a limited effect on hardening depth.

Manganese (Mn): Significantly enhances hardenability by stabilizing the austenite phase.

Chromium (Cr) and Molybdenum (Mo): Promote carbide formation, improving wear resistance and hardening depth, while reducing the risk of brittle fractures.

Nickel (Ni): Enhances toughness and corrosion resistance, with a slight increase in hardening depth.

4. Microstructural Changes After Heat Treatment

Hardenability determines the microstructure of steel after heat treatment, which directly influences its mechanical properties:

Martensite: High hardness but high brittleness, typically formed during rapid quenching.

Bainite: Good toughness and strength, formed at moderate cooling rates.

Sorbite: Formed after tempering, suitable for applications requiring high toughness.

Pearlite: Formed at slow cooling rates, typically lower hardness but good ductility.

5. Industrial Applications of Hardenability

Hardenability selection is critical for various industrial applications:

Automotive Parts: Components like gears and bearings require high surface hardness and core toughness. Steel with good hardenability can extend the life of these parts.

Heavy Machinery: Large components like drive shafts and hydraulic cylinders need deep hardening to handle heavy loads.

Aerospace Industry: Turbine components must withstand high-temperature and high-pressure environments, making hardenability and wear resistance crucial.

Hardenability and its Calculation

If products with large cross-sections use steel with low hardenability, it may not harden sufficiently in the core, failing to meet strength requirements. Additionally, impact resistance or fatigue resistance may decrease, leading to unexpected failures.

Therefore, it is essential to select steels with appropriate hardenability based on usage conditions.

For high-load or large-section products, steels with excellent hardenability must be used.

In applications requiring frequent quenching with high precision, steel with low transformation temperature or self-hardening properties should be selected.

In mass production, steels with minimal hardenability variation between batches must be chosen to ensure product consistency.

The hardenability of steel is determined by its chemical composition and grain size.

Elements like carbon, manganese, chromium, and molybdenum contribute to improving hardenability, and even small additions can effectively enhance it.

Water quenching or oil quenching provides better hardening penetration but also increases the risk of distortion and cracking.

Therefore, when selecting steel and designing the conditions for use, appropriate quenching operations must be considered to optimize performance.

The degree of hardenability determines how deep the steel can harden during the quenching process.

Steels with higher hardenability perform better in thick-section components and exhibit a smaller mass effect, meeting the needs for high strength and high-load applications.

The hardenability of steel varies depending on the cooling medium, alloy composition, and heat treatment method. Therefore, appropriate consideration must be given when selecting steel based on actual application requirements.