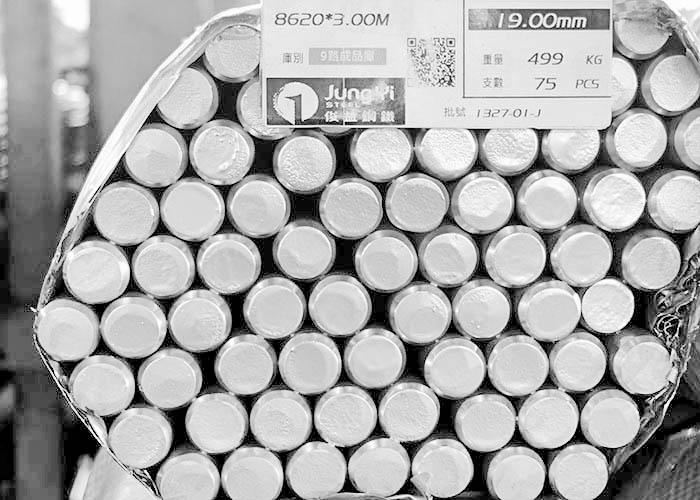

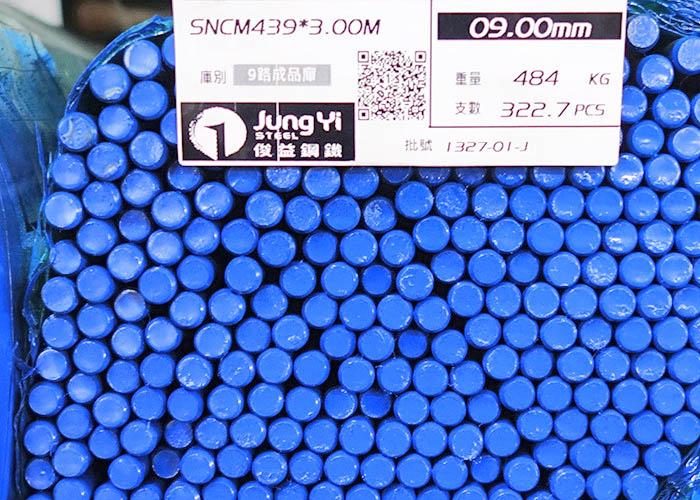

Nickel Chromium Molybdenum Steel for Machine Structural use (SNCM)

Ni Cr. Mo. steel is a material that has Mo. element (<1.0%) added, to acquire its strength and toughness and become the most excellent steel type among all kinds of structural steel.This steel has good yield strength and resistance to stubbornness, good hardening performance, high toughness, high wear resistance and impact resistance.

㈠ Chemical Composition

⒈ Carbon (C): 0.2% - 0.4%

⒉ Nickel (Ni): 1.0% - 3.5% - Provides high toughness and good corrosion resistance.

⒊ Chromium (Cr): 0.5% - 1.5% - Enhances wear resistance and corrosion resistance.

⒋ Molybdenum (Mo): 0.2% - 0.5% - Increases high-temperature strength and toughness, improves hardenability.

⒌ Manganese (Mn): 0.3% - 0.8% - Increases strength and hardness.

⒍ Silicon (Si): 0.15% - 0.5% - Improves strength and hardness.

⒎ Sulfur (S) and Phosphorus (P): Low content, each below 0.035%, to minimize adverse effects on steel properties.

㈡ Properties

⒈ High strength and toughness: Addition of nickel and chromium significantly improves the strength and toughness of the steel, allowing it to perform well in high-strength applications.

⒉ Excellent corrosion resistance: Combination of nickel and chromium gives the steel excellent corrosion resistance, especially in harsh environments.

⒊ Good heat resistance: Presence of molybdenum allows the steel to maintain good strength and stability at high temperatures.

⒋ Good hardenability: Addition of nickel and molybdenum improves the steel's hardenability, enabling more uniform hardness distribution during heat treatment.

⒌ High wear resistance: Chromium enhances the steel's resistance to wear, suitable for use in high-wear environments.

⒍ Weldability: Nickel-chromium-molybdenum steel exhibits good weldability but requires proper preheating and post-weld heat treatment to prevent welding cracks.

⒎ Machinability: Has good machinability, suitable for applications requiring high wear resistance.

㈢ Heat Treatment

⒈ Quenching:

Heating to austenitizing temperature (850-950°C), then rapidly cooling (typically in oil or water) to increase the steel's hardness and strength.

⒉ Tempering:

Heating the quenched steel to tempering temperature (500-700°C), then slow cooling to reduce quenching stress and increase toughness.

⒊ Normalizing:

Heating to slightly above austenitizing temperature (850-950°C), then cooling in air to achieve uniform steel structure and improve mechanical properties.

⒋ Annealing:

Heating to appropriate temperature (650-750°C), then slow cooling to improve machinability and stability.

These translations aim to accurately convey the technical details and characteristics of the steel and its heat treatment processes.