High Speed Tool Steel (SKH)

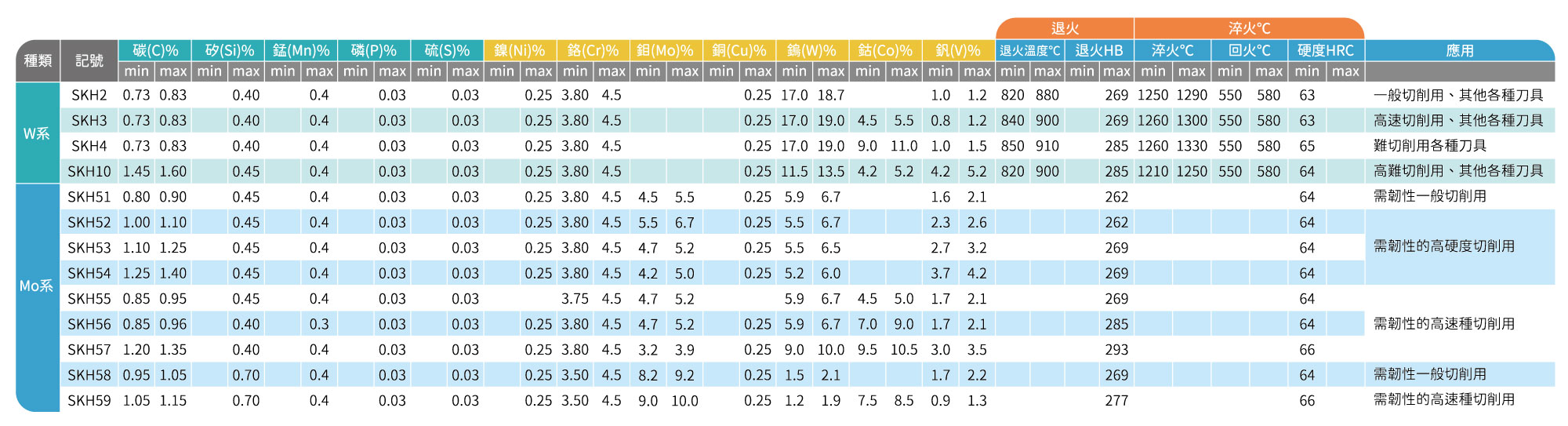

High speed steel has been used to produce highly efficient cutting tool that can avoid getting softened by annealing when there is high heat (approx. 600˚C) caused by the friction at the blade. Other attributes such as thermal-setting, wear-resistance, high strength, consistent hardness and machining performance can be seen. Under high heat, instead of getting softened, its hardness increases; this is called “red hardness” or “secondary hardening.” Based on chemical element, there are 5 categories of high speed steel : W. series, Mo. series, W. Mo. series, V. series and Co. series. If categorized by performance, there are 3 types: low-alloy, regular and high-performance. W. series high speed steel, the most typical ones are JIS SKH2~10, contains up to 12w.t.%, so they possess superior strength, hardness and wear-resistance. As for Mo. series, the most typical ones are JIS SKH51~59 because of optimum heat-resistance and wear-resistance.