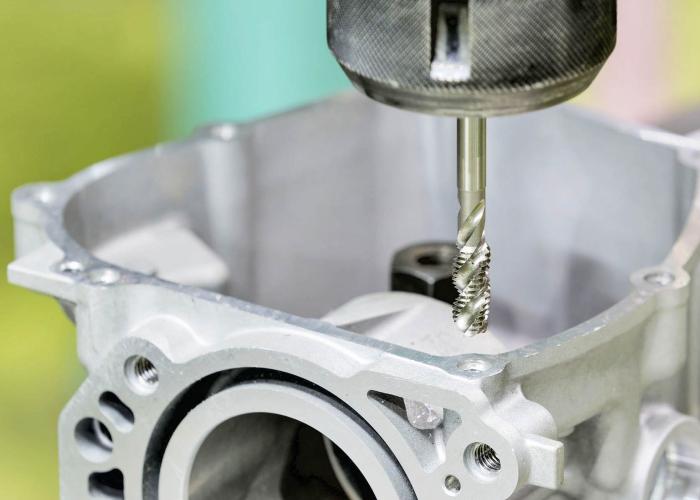

Carbon Tool Steel (SK)

Carbon tool steel has been an important material in mechanical fabrication, for example, measuring gauge, cutting tool and dies are made of high carbon steel (0.6~1.5% carbon). Other alloy elements such as Cr., Mn., Ni., Mo., V., W., and so on, are added depending on different purposes. By chemical elements added, there are tool steel, alloy steel and high-speed steel; if by purposes, there are tool steel for machining, impact-resistant, wear-resistant and heat-resistance. The characteristics of carbon tool steel include: easy to conduct heat-treatment, good toughness and wear-resistance, not softened in high temp., easy and low-cost fabrication. However, the machinability can be reduced in high temp.. Therefore, it is necessary to conduct hardening and tempering for strength, hardness, wear-resistance and toughness. Besides, before hardening process, conduct spheroidizing to make cementite spheroidized.