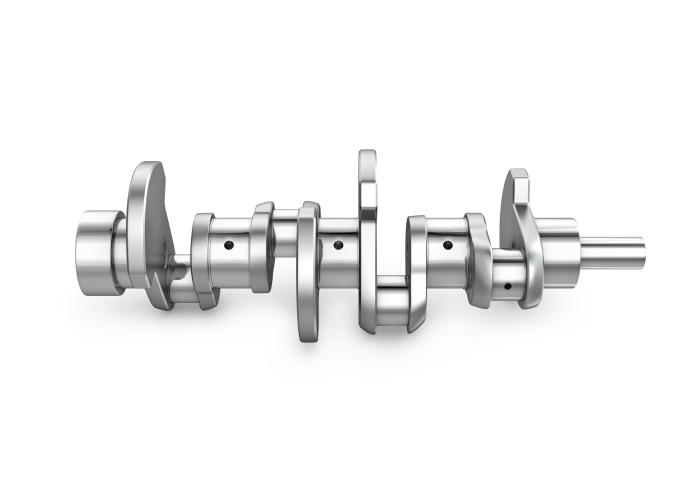

Manganese Steel for Machine Structural use (Mn)

Mn. Steel has high strength and has been applied to critical circumstances in which the material would undergo impact, squeezing and wear coming from high stress and abrasives. It has been widely used to produce the lining of Ball Mill, hammer of Hammer Crusher, jaw plate of Jaw Crusher, the concave of Conic Crusher, crushing concave, bucket and tooth of excavator, turnout of rail, tracks of tractor and tank, which are made of anti-impact and wear-resistant cast. In addition, it can be applied to bullet-proof steel plate and safe deposit box as well.