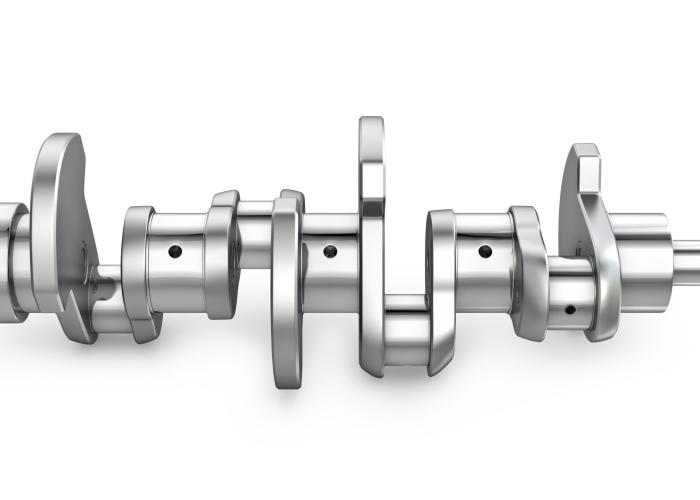

Chromium Steel for Machine Structural use (SCr)

Chromium Steel for Machine Structural use

Cr. is one of the elements added to heat-resistant steel. Cr. steel stands for alloy steel that contains Cr. and features material hardness, wear-resistance, corrosion and rust resistance and applicability for making machinery and tools. Cr. can offer higher anti-oxidation and corrosion resistance. In order to possess specific performances for different environment, some chemical elements such as Mo., V., W., Ti., Nb. And B., etc. are added to. For example, if 1% Cr. is added to, the hardenability and high temp. tempering resistance will increase and obtain tissue of higher toughness.