Magnesium Alloy Bars

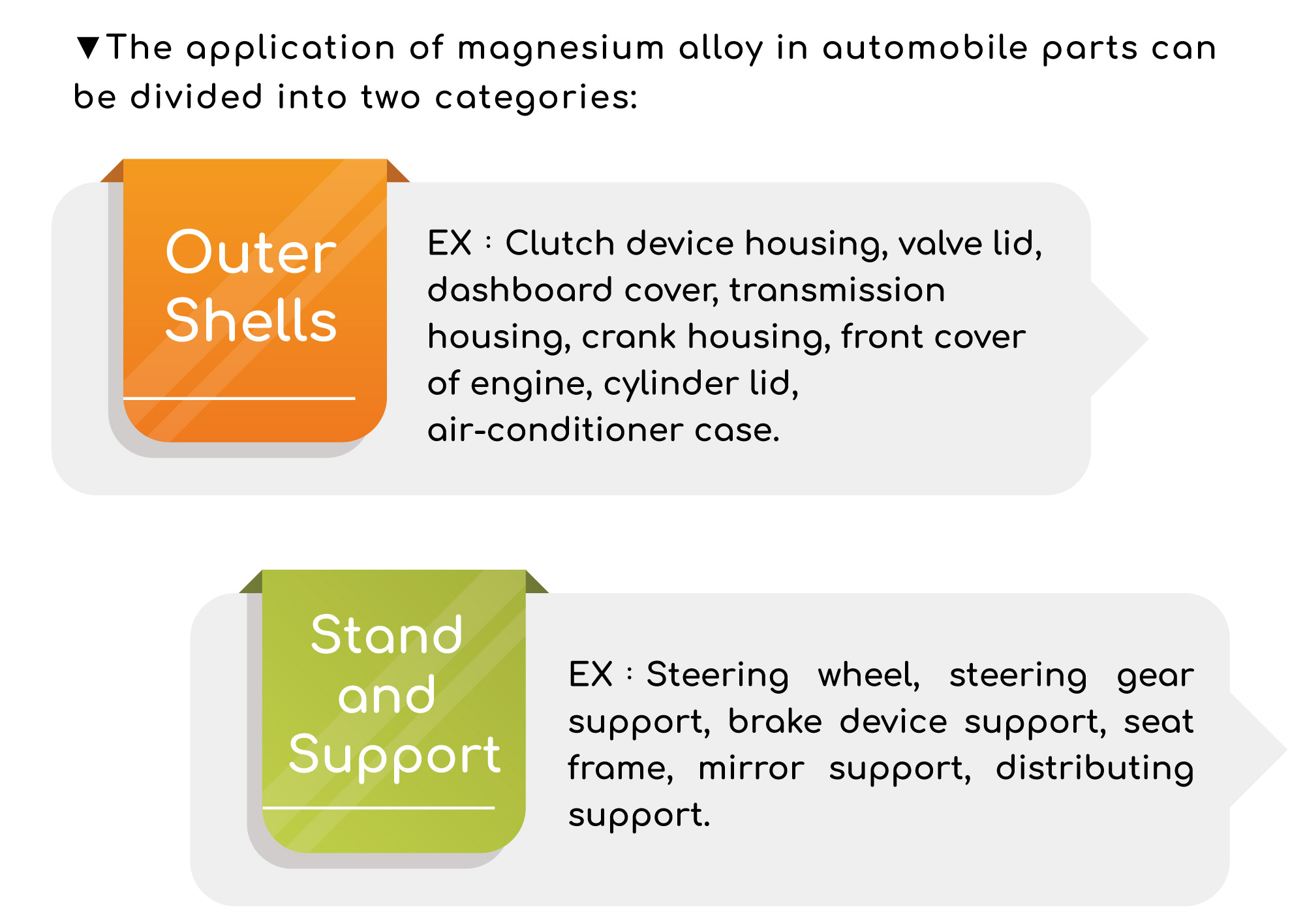

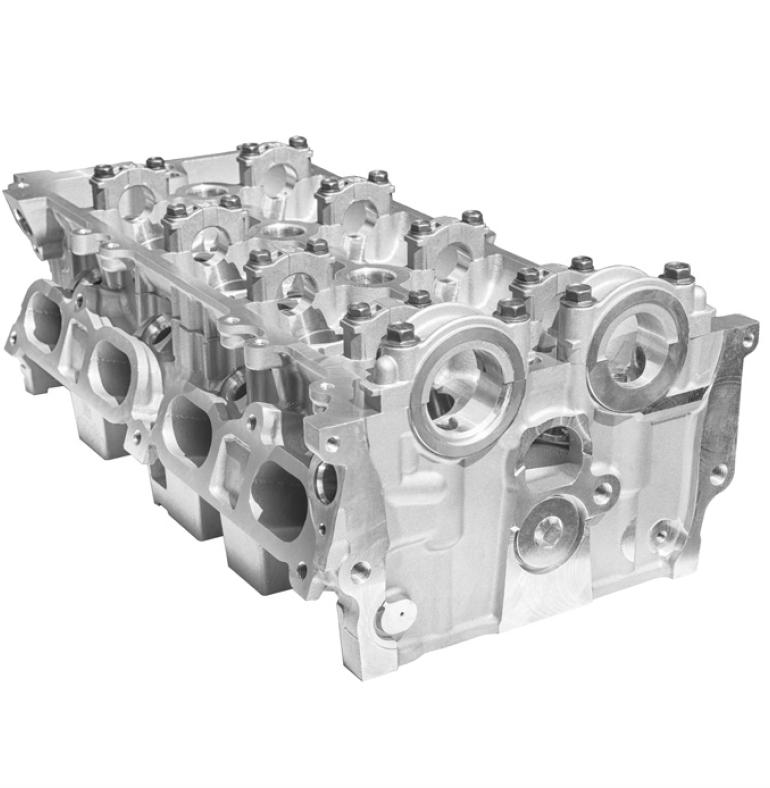

The fire-resistance of magnesium alloys are apparently inferior to that of other metals but still possess various advantages such as: better abilities of shock-absorb, electromagnetic and radiation shielding and 100% recycling and reusability make magnesium an ideal material for parts that should undergo excessive shock and vibration. However, it has been gradually replaced by Al. alloys or compound materials due to its risk of dust-explosion and low machinability.