Alloy Tool Steel (SKD, SKS)

SKS, SKD and SKT Series

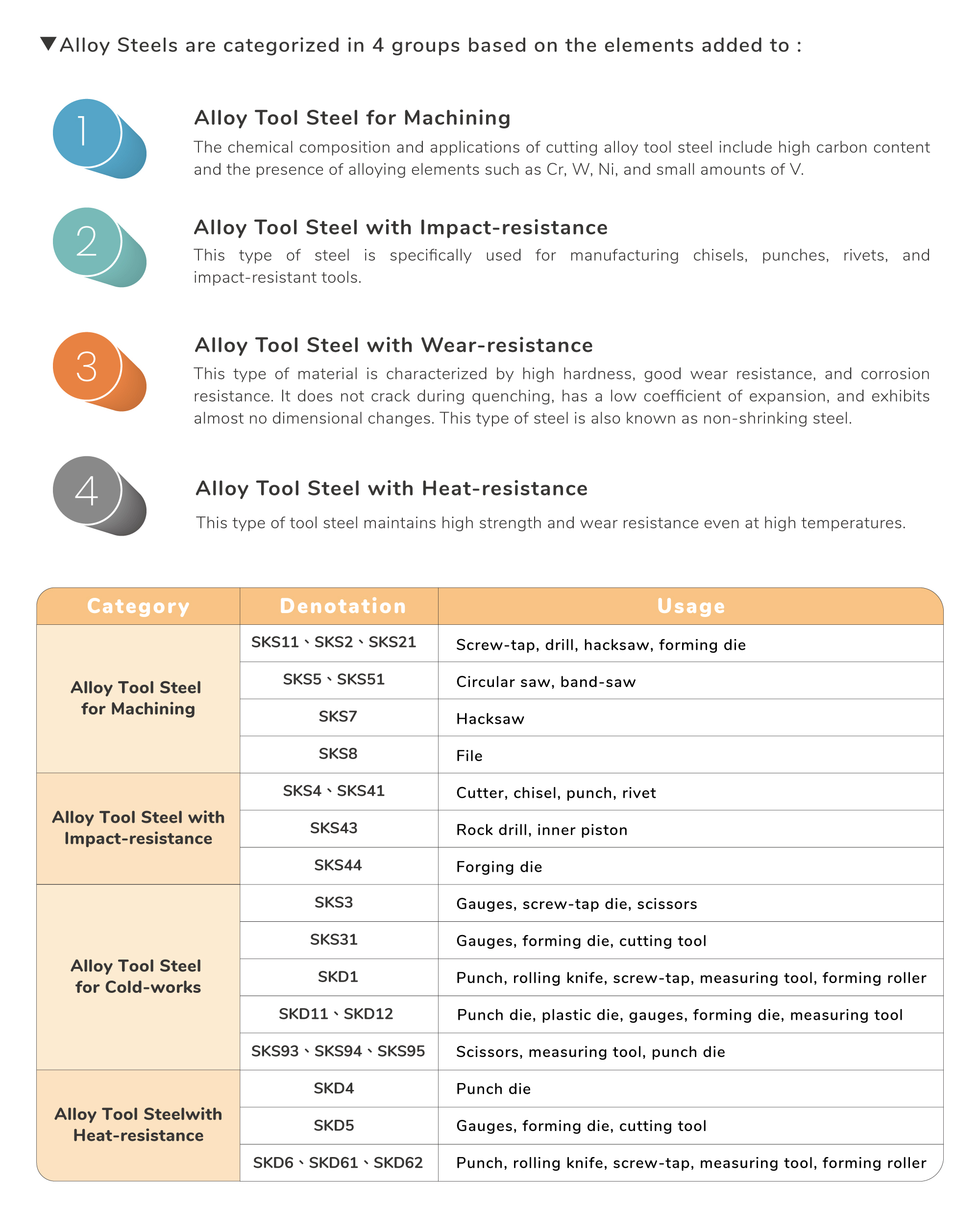

Alloy tool steel is a type of steel in which alloy elements such as chromium, molybdenum, tungsten, and vanadium are added to the carbon tool steel to improve hardenability , toughness, wear resistance, and heat resistance .

It is mainly used to manufacture measuring tools, cutting tools, impact-resistant tools, cold and hot molds and some special-purpose tools.

In the carbon tool steel added Si, Mn, Ni, Cr, W, Mo, V , etc. alloying elements in the steel .

Adding Cr and Mn can improve the hardenability of tool steel , and other elements can be selectively added or added at the same time (the total amount is generally not more than 5%) to form a series of alloy tool steel.

.jpg)